Discover the Perks of Using a stretch wrapping machine for Reliable Packaging Solutions

In the globe of packaging remedies, effectiveness is key. Automation has actually produced significant developments, such as the stretch wrapping machine. With its ability to cover items firmly and rapidly making use of stretchable plastic movie, it offers a high level of accuracy and speed. It's not almost wrapping things, but likewise concerning lessening labor prices, decreasing waste, and keeping aesthetic charm. So, what makes these equipments a game-changer in the packaging market?

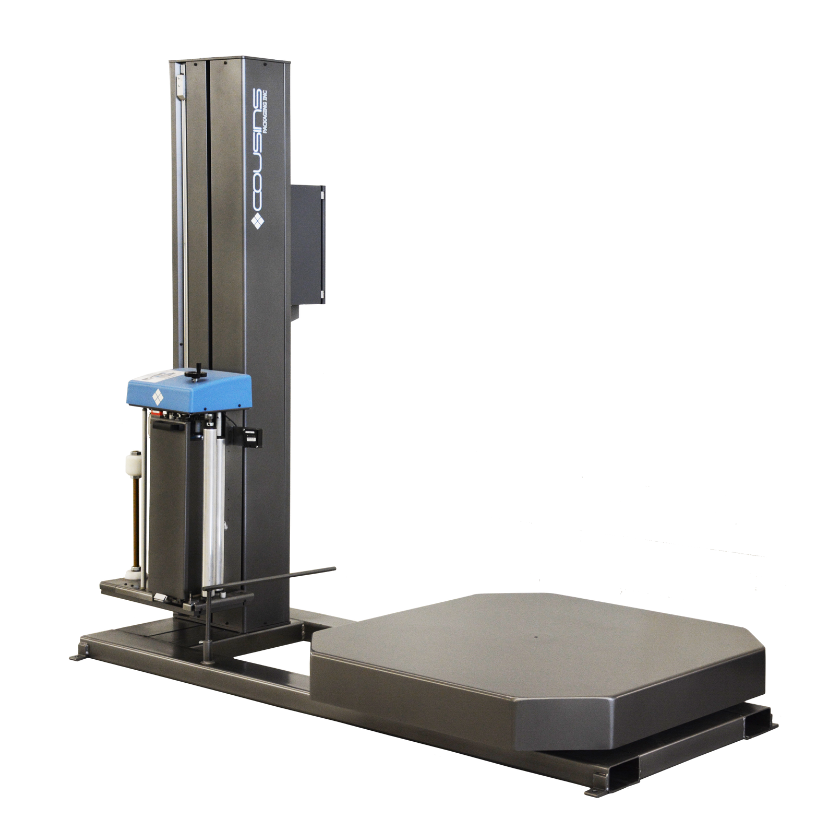

Recognizing the Functionality of Stretch Wrapping Machines

Spearheading the packaging market, stretch covering machines improve the procedure of firmly packaging things for transportation or storage. These advanced makers use a straightforward yet effective system, using an elastic plastic movie that is wrapped around items, offering security and defense. The things, frequently organized on a pallet, are turned as the movie is given, ensuring a tight and protected cover.

The movie's elasticity serves a double function: it securely binds the things with each other, lowering the threat of damages as a result of activity, and it gives an obstacle against dust, moisture, and other prospective unsafe components. The transparent nature of the stretch movie permits for very easy recognition of the packaged products.

The devices vary in their procedure setting, with some being semi-automatic, needing very little human intervention, and others being fully automated, with the ability of separately handling the entire covering procedure. Regardless of their setting, stretch wrapping devices are a cornerstone of safe and reliable product packaging.

How Stretch Covering Machines Enhance Efficiency

Increasing productivity degrees considerably, stretch wrapping makers improve the packaging procedure with their automated capabilities. These innovative makers enable firms to wrap a high quantity of bundles quickly and successfully, delivering a regular wrapping result that hands-on approaches just can not match. This rate and consistency translate directly right into enhanced productivity, allowing businesses to satisfy requiring supply routines and consumer expectations.

In addition, stretch wrapping makers require very little human treatment. Once the equipment is set up and the covering criteria are configured, the equipment can operate individually, maximizing workers to concentrate on other important tasks. This automation not only minimizes labor prices but likewise eliminates human errors, making certain the quality of wrapping stays consistent.

Additionally, using stretch covering machines usually results in much less downtime. stretch wrapping machine. With their durable design and trusted operation, these devices are much less prone to malfunctions and maintenance issues, making sure uninterrupted process and improved performance

Lowering Material Waste With Stretch Wrapping Machines

While boosting performance, stretch wrapping devices additionally play an essential function in lowering material waste. The precision of these devices makes certain that each plan is wrapped with the exact amount of material required, decreasing excess waste. This accuracy not only results in a cosmetically pleasing and regular plan, but likewise contributes considerably to environmental sustainability.

Basically, the usage of stretch covering machines in a product packaging line is not just a step towards reliable productivity, however additionally a leap towards green practices by substantially lowering material waste.

Cost Decrease: A Trick Benefit of Stretch Wrapping Machines

Along with mitigating product waste, an additional significant advantage of stretch wrapping makers is their possibility for cost reduction. These devices are reliable, calling for less manual work for product packaging items, therefore cutting down on labor costs.

Additionally, stretch covering makers make use of much less material to package goods securely as compared to conventional wrapping techniques. This effective usage of products not just minimizes waste yet additionally decreases expense on product packaging products.

The makers likewise lessen damages to items throughout transport. With protected and durable packaging, the risk of item damages reductions, minimizing the expenses related to product returns and replacements.

Finally, the rate and performance of stretch covering makers can boost production rates. Faster packaging times suggest that organizations can package and deliver more products in much less time, improving general productivity.

Implementing Stretch Covering Machines in Your Packaging Process

Offered the outstanding advantages of stretch wrapping makers, incorporating them into your product explanation packaging procedure can be a game-changing decision. An analysis of the present packaging procedure is required to determine the suitable device kind and size.

Training staff on machine procedure is essential. This consists of comprehending the device's performances, troubleshooting common concerns, and sticking to security guidelines. By doing so, businesses can make certain a reliable, economical packaging process, gaining the full benefits of their financial investment in stretch covering makers.

Final thought

To conclude, stretch covering makers provide efficient, cost-efficient product packaging services. They enhance performance and minimize waste by specifically covering items with elastic plastic film, conference high-volume demands easily. These makers see here now guarantee item stability and protection, while likewise delivering cosmetically pleasing packages. For services aiming to enhance their packaging procedures, this technology supplies an effective path in the direction of enhanced efficiency and expense financial savings.

Once the device is set up and the covering criteria are set up, the machine can operate independently, freeing up workers to concentrate on various other critical tasks.While enhancing efficiency, stretch covering makers also play a critical role in reducing material waste.Given the outstanding benefits of stretch wrapping devices, integrating them into your packaging process can be a game-changing decision - stretch wrapping machine. By doing so, businesses can ensure an efficient, affordable packaging procedure, reaping the full benefits of their financial investment in stretch covering makers

In final thought, stretch wrapping devices provide efficient, cost-effective packaging remedies.